Students tour King Coal mine

The Southern Ute Indian Montessori Academy Upper Elementary class, guided by Mari Jo Owens, traveled Thursday, Oct. 24 to the King Coal II facility in Hesperus, Colo., to continue its lectures on energy.

King Coal II was established in 2007 and sits not far from the original King Coal mine, which started running in 1938 and closed in 2009. Its operators mine bituminous coal that’s sold to cement companies stretching all the way to California.

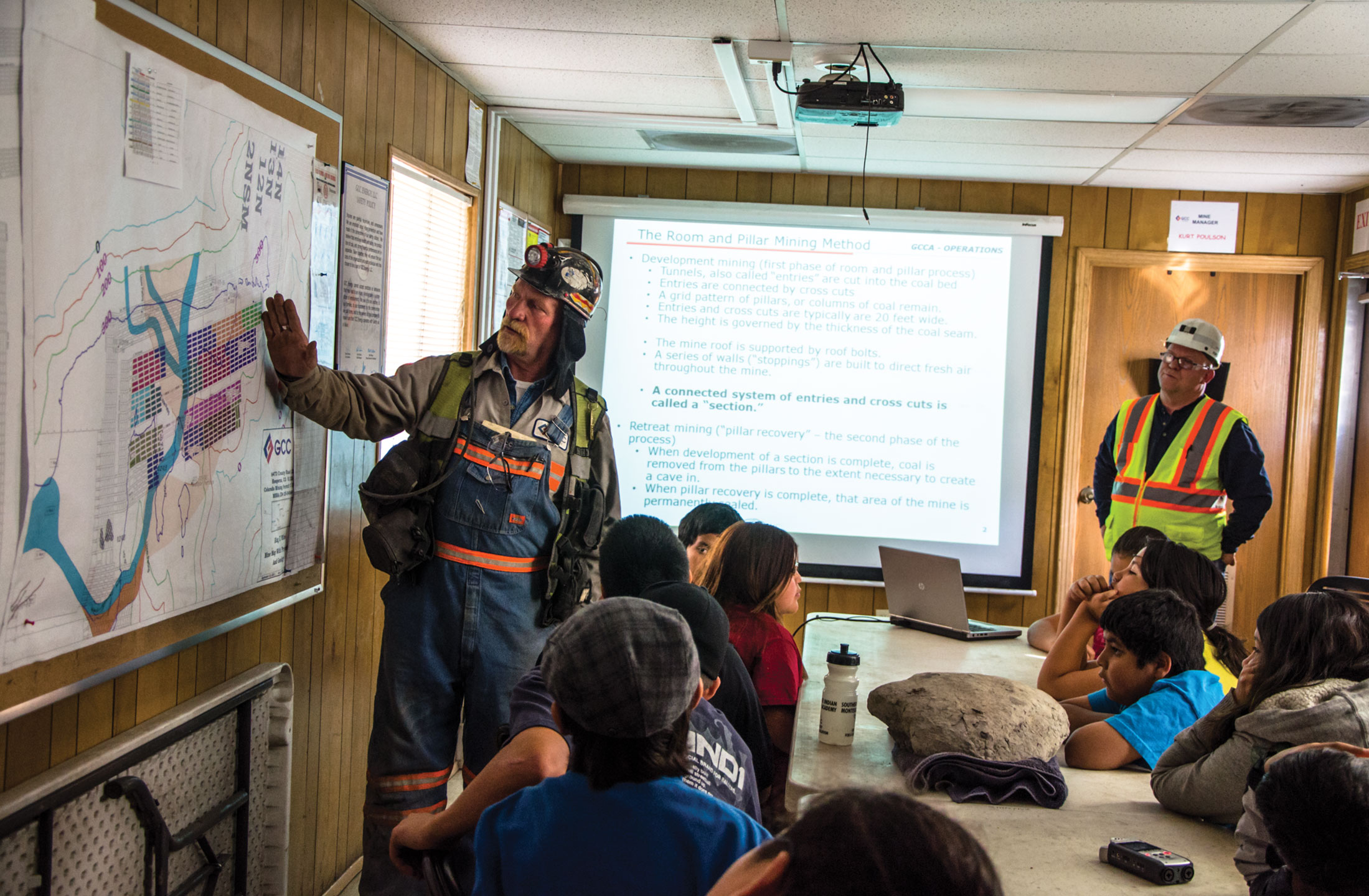

Kurt Poulson, head manager of the mine, talked to the students about running the facility. First, he showed a fossilized dinosaur footprint, which dated to 300 million years ago, discovered at one of the previous mines in which he worked.

The kids studied the imprinted rock before Poulson began to discuss the mining process.

“In the coal mining industry, there’s two different ways of mining coal,” he said. “One is room-and-pillar and the other is long wall. … We don’t long wall mine at our facility.”

He explained to the kids the procedure of room-and-pillar mining.

“The first phase of the room-and-pillar process: We do what we call developing,” he said. “Entries are cut into the coal bed. We are mining at 8 feet high in the coal seam … but it will vary depending on [the height of the seam].”

These entries then become connected by cross cuts, he said.

Mike McFarland, mineworker and safety trainer, discussed how the mine progresses.

“We drive through the [entries] and we connect them every so many feet and build walls, push air in, and build conveyer belts in there so we could keep advancing,” he said. “And then eventually we go back and take it all out.”

Poulson said pillar recovery is the second phase.

“When development of a section is complete, coal is removed from the pillars to the extent necessary to create a cave-in,” he said. “That area of the mine is then permanently sealed.”

Safety at the mine is a major subject that McFarland addressed.

“What we have is a map of a mine area and we follow these maps,” he said. “When we go in, we have surveyors that survey exactly where we’re at.”

He displayed all of his work tools, including the ones that keep him and the workers safe. A cell phone with a Wi-Fi-enabled tracking system is one of these. Miners can be tracked via GPS throughout the area if there were to be an incident.

The kids made their way near the conveyers that deposit the coal. Delivery trucks came through for their deposits while McFarland showed the type of Jeeps in which the workers head to the tunnels. Every vehicle seats eight miners.

The trip concluded after the bus took a loop around the mine where the kids peeked at the machinery and other utilities. The bus took a stop at the entryway for a quick glance.

“Unfortunately, you have to 18 or over to go in,” McFarland said.